Our Crusher Series

Explore our comprehensive range of high-performance crushers, designed to meet the rigorous demands of mining and quarrying applications worldwide.

The PE Series Jaw Crusher is a classic primary crushing machine with stable performance. It is widely used in mining, metallurgy, construction, highway, railroad, and water conservancy to crush materials with compressive strength less than 320MPa.

Specifications

Key Features

- High crushing ratio

- Simple structure & reliable operation

- Easy maintenance

- Low operating cost

The PY Series Spring Cone Crusher is suitable for crushing hard and mid-hard ores and rocks. It offers high efficiency, easy adjustment, and economical operation. Widely used in metallurgical industry, construction industry, road building industry, chemical industry and phosphate industry.

Specifications

Key Features

- High productivity and high quality

- Less machine stop time

- Easy maintenance and low cost

- Unique crushing ability

The PF Impact Crusher is designed for secondary crushing of materials with compressive strength less than 350MPa. It features a unique impact plate design and high-chrome blow bars, producing cubic-shaped end products ideal for highway and construction applications.

Specifications

Key Features

- Cubic shaped end product

- Adjustable end product size

- Blow bar with high chrome iron

- Easy maintenance

The 6-S Shaking Table is a gravity separation device used to separate fine-grained minerals based on specific gravity differences. It is highly effective for processing gold, tungsten, tin, tantalum, niobium, and other rare metals and precious metal ores.

Specifications

Key Features

- High enrichment ratio

- High separation efficiency

- Easy to adjust stroke

- Low power consumption

The Wheel Sand Washer is used to remove dust and stone powder from sand produced by the sand maker. It aims to improve the quality of sand. The reliable transmission device ensures the washing effect.

Specifications

Key Features

- High cleanliness

- No pollution

- Little loss of sand

- Simple structure

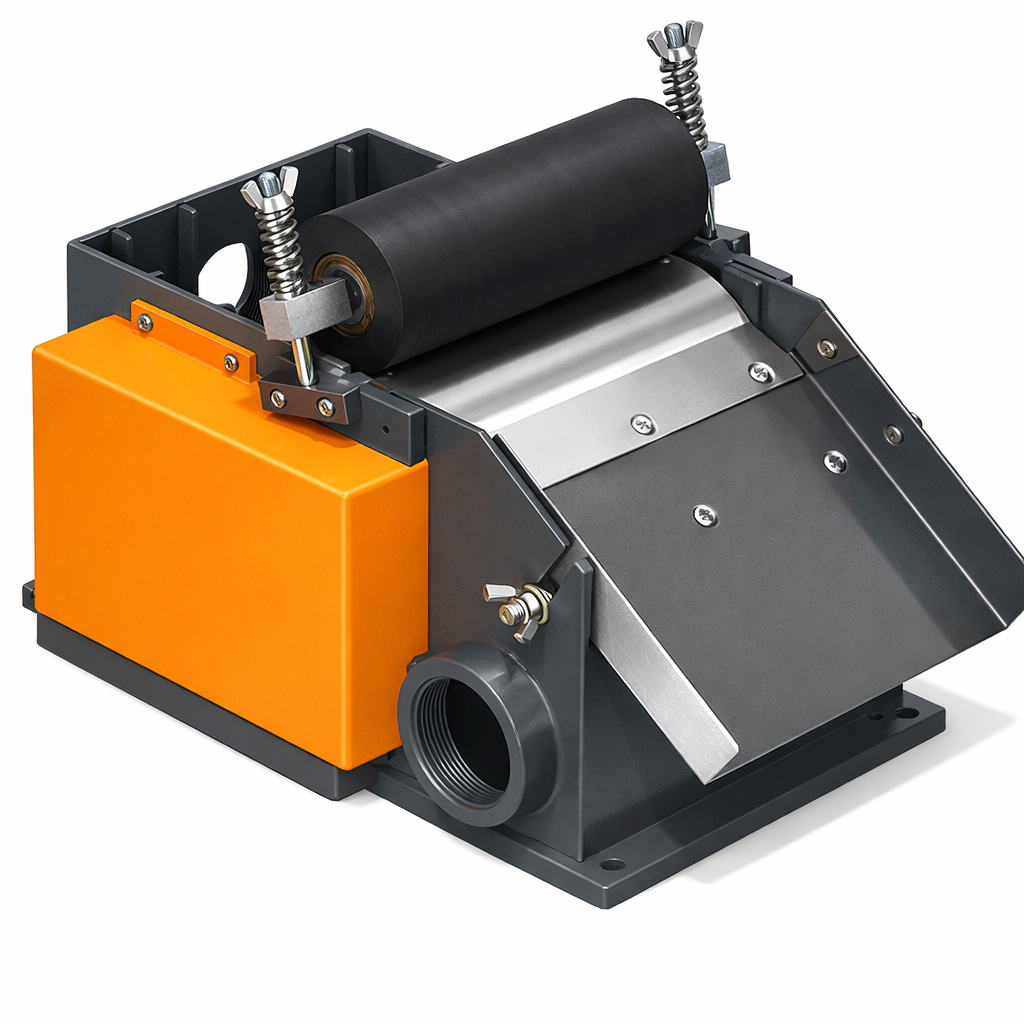

The CTB Series Wet Magnetic Separator is designed for separating strongly magnetic minerals from non-magnetic minerals. It is also used for removing iron from non-metallic minerals like coal.

Specifications

Key Features

- High recovery rate

- Optimized magnetic system

- Wear-resistant drum

- Low maintenance

Ready to Optimize Your Mining Operation?

Our engineers are online and ready to design a custom solution for your project. Get a free consultation and quote today.